PROFILE GRINDING: GRINDING LARGE GEARS

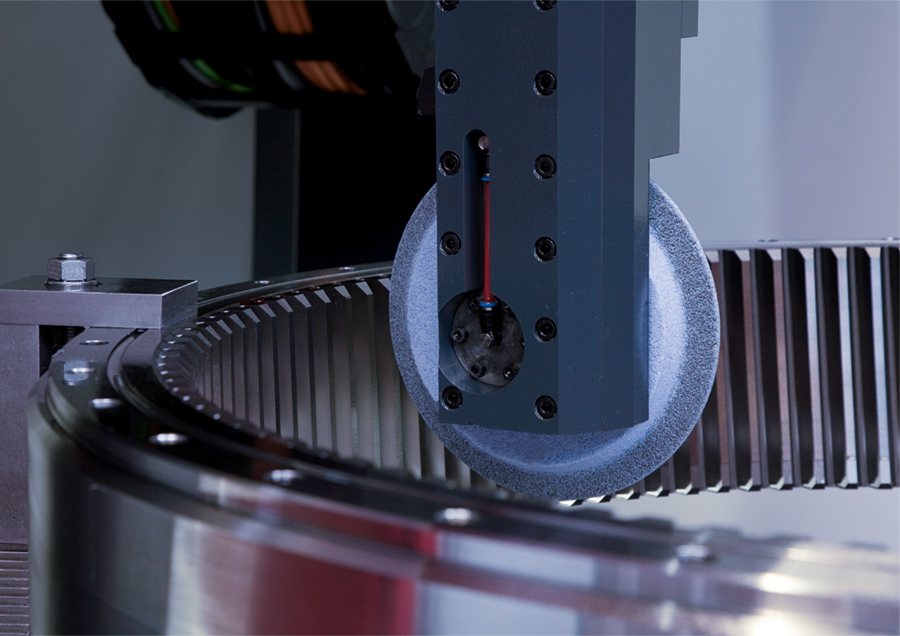

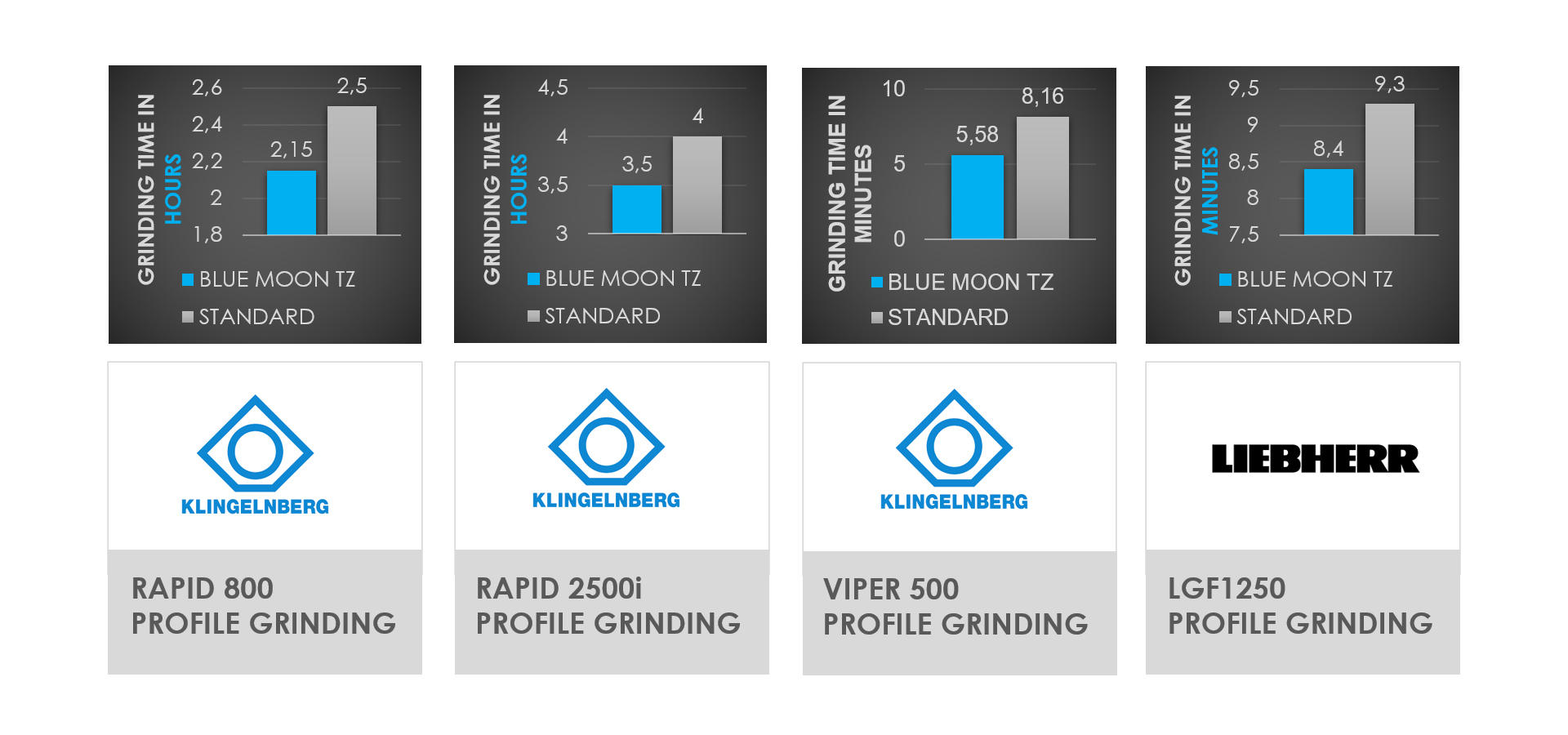

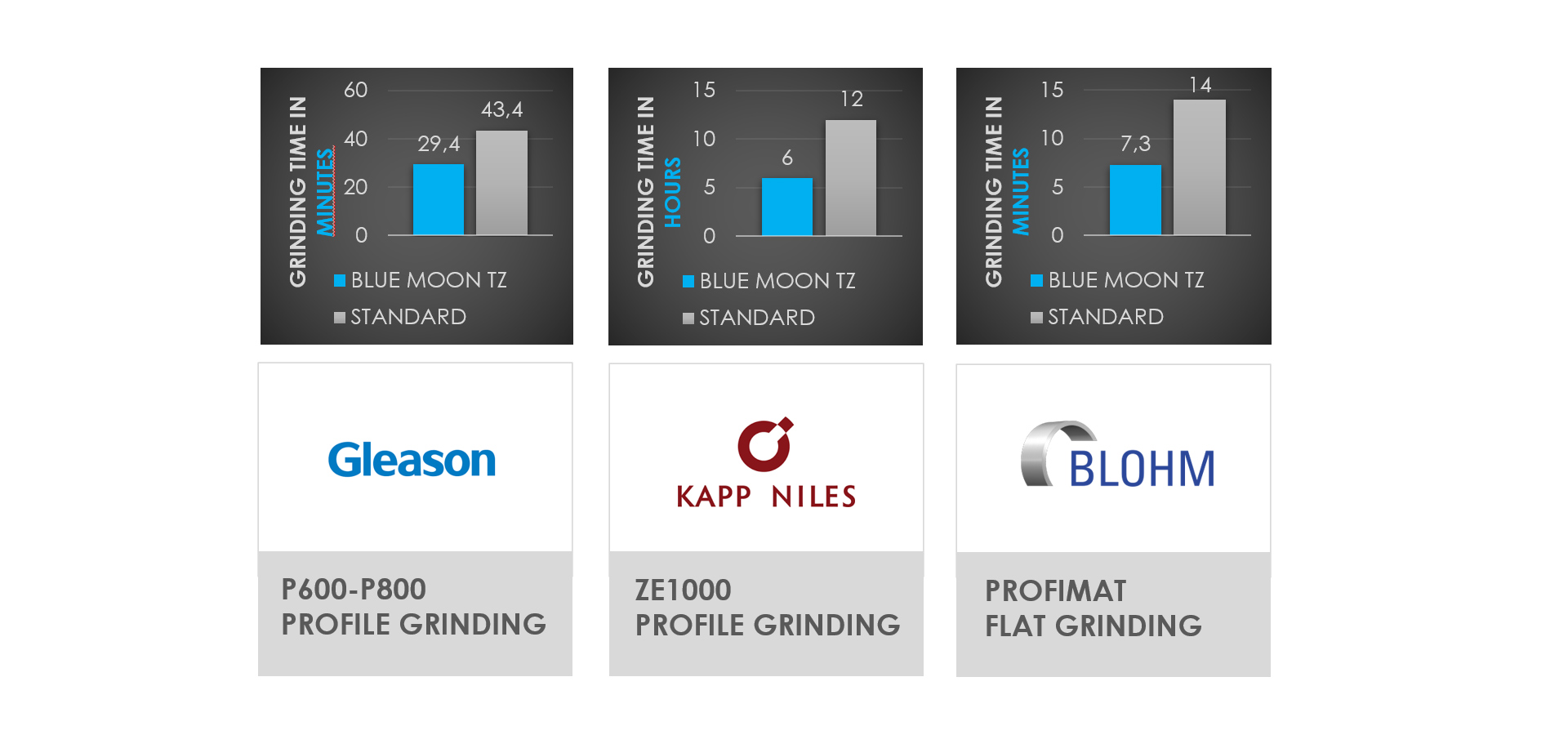

Serial production of large gears requires a high level of quality, excellence and continuity in production. Particular emphasis is placed on maximum synergy between the grinding machine, the grinding process and the grinding wheel. After several successful trials on various Klingelnberg Höfler Rapid grinding machines carried out by Krebs & Riedel with customers in their production facilities, Krebs & Riedel has received several large orders for grinding large gears from abroad and has introduced the new premium grinding wheels with high process reliability. Krebs & Riedel is one of the world's leading manufacturers of grinding wheels for gear grinding in the automotive and EV sector. The family-owned company is also expanding into other sectors where large gears are manufactured with the new Blue Moon™ TZ premium product range.